Congress Acts to Eliminate Mercury from Chlorine Plants

Press Release Date: September 30, 2009

Location: Washington, DC

Contact:

Anna Baxter | email: abaxter@oceana.org

Anna Baxter

Following the Obama Administration’s international statement about the need to control mercury, a bill that would phase-out the use of mercury in chlorine production, was reintroduced in the House of Representatives. This mercury bill was originally authored by President Obama while serving as senator of Illinois.

The bill, H.R. 2065, would require the remaining four chlorine factories that use a mercury production process to stop doing so within two years of passage. The use of mercury-based technology by these plants causes the release of the toxic chemical into air and water, as well as contamination of the chlorine plants’ products, especially chlorine’s co-product, caustic soda.

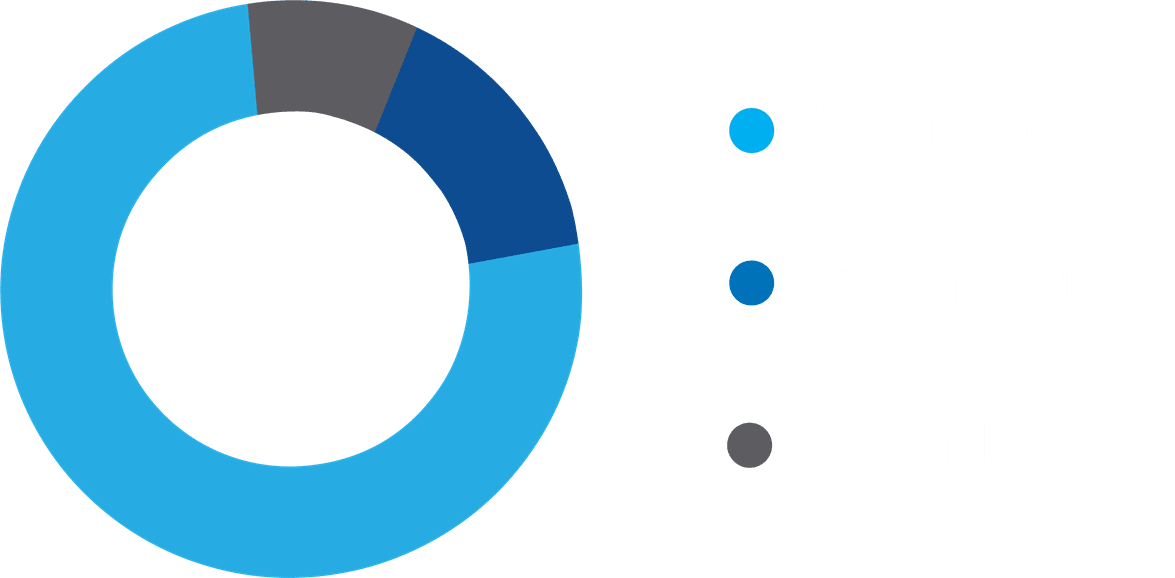

While 95 percent of chlorine produced in the United States uses a mercury-free process, four U.S. plants have continued to use an outdated mercury-dependent approach that releases the contaminant into the air and water surrounding the plant.

This contamination is entirely unnecessary because modern methods for chlorine production have been available for decades and are mercury-free. Lead bill sponsor Rep. Jan Schakowsky (D-IL) has garnered support from many of her colleagues for the bill.

“More than 100 facilities have already switched to mercury-free technology,” said Congresswoman Schakowsky. “Switching to cleaner membrane-cell technology improves chlorine plant operating efficiencies, creates higher profits and saves jobs. These benefits, along with reduced mercury pollution in the plant communities, are a win-win outcome for the companies and public health,” she added.

These four plants have failed to make investments in clean technology that would help them become more competitive in their industry. Modernizing these plants with cleaner technology would help make them more efficient over the long-term and save local jobs.

“Failing to keep pace with their competitors puts jobs at risk at these four chlor-alkali plants,” said Jacqueline Savitz, senior pollution campaign director for Oceana. “But modernizing protects jobs, saves money and prevents mercury pollution,” she added.

For example, the Olin Corporation plant in Augusta, GA could save an estimated $17.6 million in energy costs alone over five years, according to Oceana’s calculations.

While coal-fired power plants remain the leading source of mercury pollution, these chlorine factories release more mercury than the average coal-fired plant, making them top emitters in their states. For example, the Olin Corporation facility in Tennessee has historically been the number one source of mercury pollution in the state, and the plant has impaired the river on which it’s located, according to local environmental officials. The PPG Industries facility in West Virginia has failed to comply with mercury discharge limits in recent months, and the Olin facility in Augusta, Georgia has contaminated a canal on the Savannah River so badly that the state of Georgia has required the company to clean it up.

Mercury use in these plants also contributes to mercury contamination of caustic soda, a chlorine co-product which is frequently used to make high-fructose corn syrup and other food items. Recently, traces of mercury have been found in common food items, such as chocolate syrup and soft drinks. Using mercury-free technology would reduce the risk of further food contamination.